Facts About Aws Cwi Uncovered

Facts About Aws Cwi Uncovered

Blog Article

Everything about Aws Cwi

Table of ContentsThe 9-Second Trick For Aws CwiThe 7-Minute Rule for Aws CwiAws Cwi Can Be Fun For AnyoneRumored Buzz on Aws CwiThe 4-Minute Rule for Aws Cwi

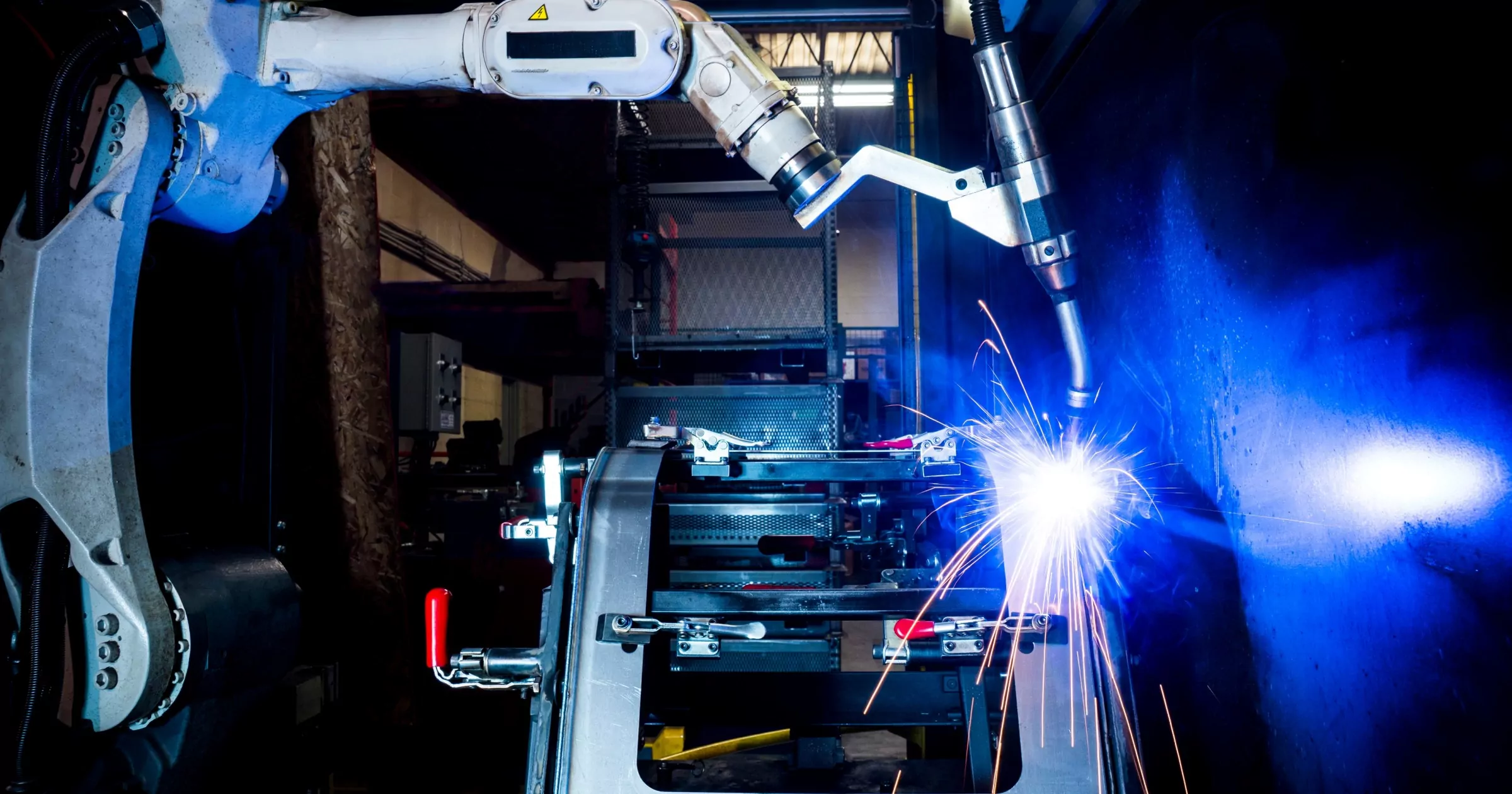

Have you ever before thought about an occupation as a welding assessor? A welding assessment accreditation is not only a fantastic accomplishment, it validates your capabilities in the welding sector.

Coming To Be a Licensed Welding Assessor reveals your dedication to growing within the welding sector. This qualification is one that should not and will certainly not be forgotten! As a CWI, you'll have the ability to capitalize on a variety of different chances amongst market specialists.

As you might recognize, welding is one of the most complicated solutions within the metal fabrication sector (https://papaly.com/categories/share?id=273a3f2a2b4b468095e296e4b0aec364). The outcome of every welding project is extremely reliant upon private welder ability.

The Single Strategy To Use For Aws Cwi

There's no question that CWIs assistance to maintain higher degrees of consistency and quality to the welding divisions they look after. This blog message gives a brief review of the primary benefits of working with a steel fabrication company that employs qualified weld examiners. It's not unexpected that the majority of prominent sectors will certainly need you to work with certified welding inspectors to manage welding.

Certified welding examiners have years of experience and hence, they understand the nuances of conformity with welding codes. Complying with the welding process, CWIs can perform a series of test to examine the quality of a weld, consisting of aesthetic assessment, heat treatment and a hydrostatic examination. Welding Inspection Company. They can likewise make the proper modifications to the pre-weld prep work and the in-weld procedures as required

An in-house certified welding inspector will have the ability to guarantee that your task is tailored to all the demands of pertinent welding codes, ensuring its top quality. Welding examiners can review welding treatment specs, structure and welding strategies, devices calibration and welding products. A welding inspectors ability to supply welding procedure specifications supplies the steel fabrication company a substantial side of the competition, enabling producers to develop welds that best match private components, as opposed to using reliable welds.

All About Aws Cwi

As previously discussed, a CWI is not only responsible fore writing the procedures for the weld, but additionally the quality-check testing procedures. https://sitereport.netcraft.com/?url=https://awscwi.com. Past that, welding inspectors work to guarantee that devices is effectively prepped for the job which welders have the ability to finish their welds with proficiency (CWI Welding Inspector). A certified welding inspector will have had years of experience, which a metal construction company can utilize to ensure excellent outcomes for all construction tasks that include welding

This is why it's crucial to find a welding firm with a seasoned and highly trained in-house certified welding examiner on personnel. CAMM steels is such an organization, so contact us today if you have a forthcoming job that calls for top quality customized welding! It's clear that a customized steel manufacture vendor with in-house CWIs has actually committed to investing in the quality of its welds.

Below at CAMM Metals, after the welding section of the job is full, we supply numerous in-house services. These services consist of weld assessment with color penetrant, acid cleansing and polishing of stainless steel welds.

For those consumers that call for certified welds, we can license our welds to AWS D1.1 & AWS D1.6.

The Single Strategy To Use For Aws Cwi

It's essential to keep in mind that many employers don't constantly require welders to be licensed. The main distinction is that qualified welders have actually written records of their examination results and their efficiency is constantly checked with periodic evaluation( s) being part of the performance document for each welder.

Prior to taking the examination all PFS welders are trained, if required, in the actual welding process that they will be utilizing and they will need to have a working knowledge of the welding devices, welding consumable and the material to be welded. Effectively passing one test will certainly enable the welder to deal with lots of kinds of constructions Will not enable him to function on all kinds of construction as there are certification varies imposed for each examination setup.

Important variables consist of however are not limited to product kind, palatable kind, product density and welding position. etc. After the welder has actually completed his test read more plate or pipeline the weld is checked making use of the adhering to NDE processes: Aesthetic Evaluation X-Ray Fluid Penetrant Screening Sometimes, the weld is additionally destructively tested.

The smart Trick of Aws Cwi That Nobody is Talking About

PFS completes this utilizing a continuity record that information all welds that a welder makes. If a welder does not utilize the welding procedure in a 6-month period, then they will be requalified because process. The benefits to using a qualification system are many however the major advantages are: It validates the skill of an individual to perform based on a qualified welding treatment specification (WPS) to generate a good weld.

Report this page